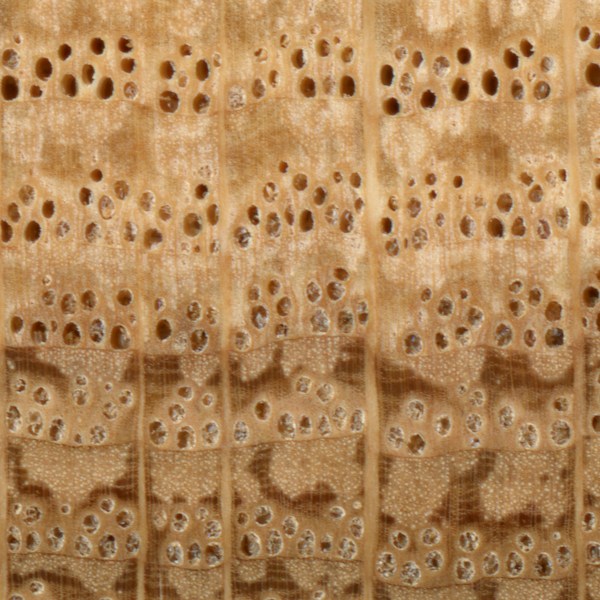

The pores found in the growth rings on red oak are very open and porous, and should be easily identifiable. White oak, however, has its pores plugged with tyloses, which help make white oak suitable for water-tight vessels, and give it increased resistance to rot and decay. The presence of tyloses is perhaps the best and most reliable way to distinguish the two oaks, but it comes with a few caveats:

1.) Make sure that you’ve cleaned up the endgrain enough to see the pores clearly, and blown out any dust from the pores. You don’t want a “false-positive” and mistake sawdust clogged in the pores for tyloses.

2.) Make sure that you’ve viewing a heartwood section of the board in question. While white oak has abundant tyloses in the heartwood, it is frequently lacking in the sapwood section.

One related test regarding porosity is to take a short section of oak and try to blow air through the pores. If you are able to blow anything through it at all, it’s probably red oak. Take a look at this video, where a red oak dowel was used to blow bubbles in water:

One exception to this rule is chestnut oak, which is still considered to be in the white oak group, even though its pores are open like red oaks.

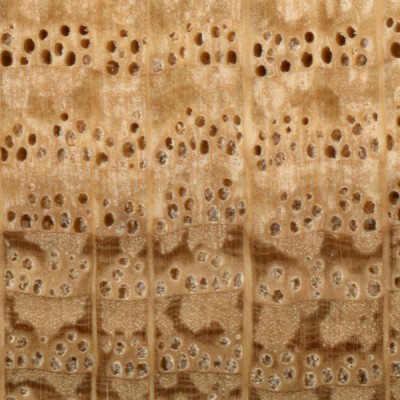

2. Look at the rays

When looking at the face of the board, especially in the flat-sawn areas, you may notice little dark brown streaks running with the grain, sometimes referred to as rays.

Look closely at the picture above, (click on it to enlarge it if you have to), and note the length of the rays in both types of wood. Red oak will almost always have very short rays, usually between 1/8″ to 1/2″ long, rarely ever more than 3/4″ to 1″ in length. (Pictured above on the right.)

White oak, on the other hand, will have much longer rays, frequently exceeding 3/4″ on most boards. (Pictured above on the left.)

This method is probably the most reliable under normal circumstances, and is useful in situations where the wood is in a finished product where the endgrain is not exposed.

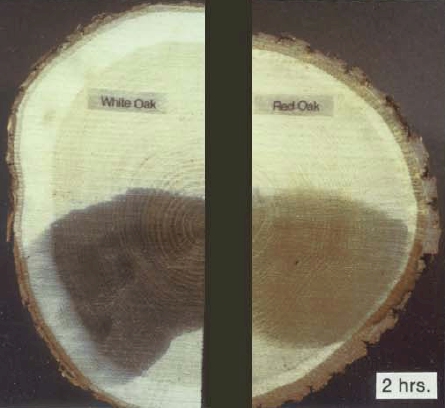

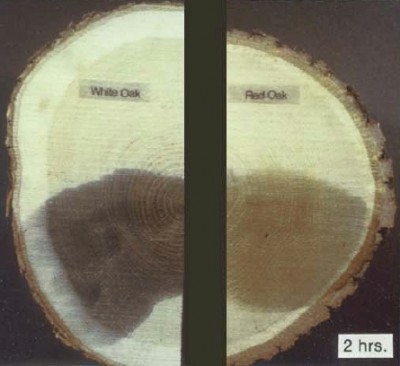

3. Use sodium nitrite

This technique is sometimes used at sawmills if various logs need to be sorted out quickly. Instead of taking the time to analyze each log closely by hand, a 10% solution of sodium nitrite (NaNO2) is sprayed or brushed onto the wood and observed. If it’s red oak, there will only be a small color change, making the wood only slightly darker. But if it’s white oak, there will be a noticeable color change in as little as five minutes, (though it can take longer if the wood is dry, or if the temperature is low). The heartwood of white oak will eventually change to a dark indigo to almost black.

This method is extremely accurate and reliable, though in most instances, it’s probably overkill. However, if you’re ever in a situation where you can’t separate between red and white oak based on anatomy, this method is nearly foolproof. (Though, only the heartwood will bring about the color change, not the sapwood.)

First, you have to obtain some sodium nitrite (NaNO2). You may be able to find some locally through chemical supply stores, but they typically only sell in bulk quantities, making such a small project prohibitively expensive. However, some online retailers have the chemical for sale in much smaller quantities, bringing it into reach of most that are curious about oak identification.

Next, you need to mix up a roughly 10% solution of sodium nitrite by weight. This ratio actually isn’t as critical as it seems: solutions as small as 1% and as high as 20% have all been used with success, but to err on the side of caution, we’ll use the most appropriate quantity recommended.

Recipe for 10% Sodium Nitrite Solution for Testing Oaks:

- 1 cup water

- 4 teaspoons sodium nitrite

Directions: Stir in sodium nitrite until clear. Clearly label solution to avoid confusion; sodium nitrite is very dangerous if ingested.

All that’s left is to simply brush this solution onto a raw wood surface and wait for a reaction. With dried wood stored at room temperature, this reaction should take about 10 minutes. Red oak will be only slightly discolored by the solution, sometimes developing a slightly greenish hue, while white oak will gradually turn a dark reddish brown, eventually turning a deep indigo to nearly black.

See the progression photos below for a better look. (Also note that around the 8 and 15 minute marks the water begins to evaporate from the surface of the wood, but the color is still present after the wood has dried, as indicative of the 25 minute photos.)

TIMEELAPSED

RED OAK

WHITE OAK

raw

1 minute

1 minute

5 minutes

5 minutes 8 minutes

8 minutes 15 minutes

15 minutes

25 minutes

25 minutes