Making your own gaff is a fun and relatively inexpensive project that almost anyone can do with basic tools and components. It allows for personal customization, and the satisfaction of sticking a fish with a gaff that you made is second to none!

Materials

-

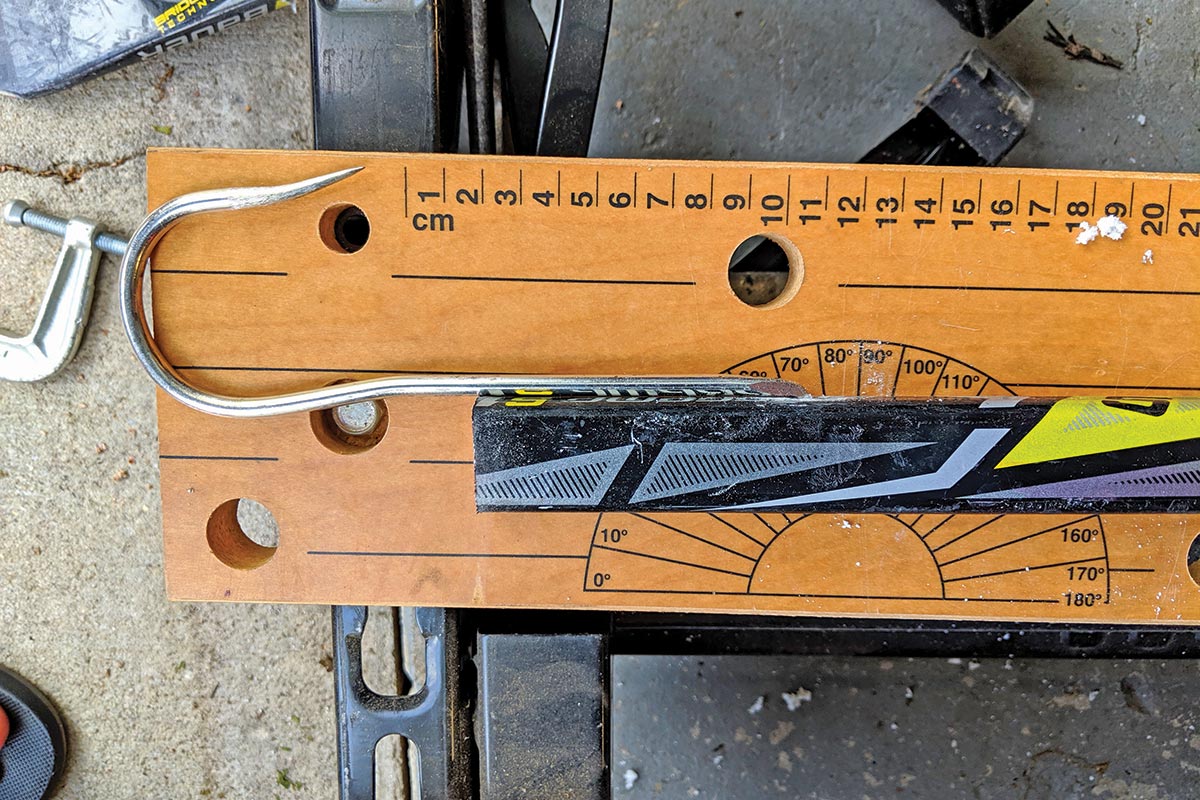

Simple materials for building a gaff, which in this example the author uses an old hockey stick as a handle. Handle

- Gaff hook

- Paracord, hockey tape, or heat shrink for grip

- Electrical tape

- Wire (Like the type to hang pictures)

- Two-part epoxy

- Drill and various drill bits

- Spray paint

First thing is to choose what size gaff hook would be best suited for the type of fishing. For smaller fish like bluefish, mahi, false albacore, or bonito, a 2- to 3-inch hook would be more than adequate. If you’re building something bigger strictly for tuna, shark, and other large offshore species, a 3- to 4-inch hook might be better. That said, a good all-around size is 3 inches which can be purchased at most tackle shops for between $5 and $10. Choosing the best material for the gaff handle is also important. Some people prefer bamboo since it is flexible and strong. Others like rigid handles like broomsticks; hockey sticks, broken rods, or almost anything else can be used as a handle, as long it is durable. The length can be customized, anywhere from a 1-foot lip gaff to an 8-foot reacher is possible. I believe 3- to 5-foot is a good multi-purpose length handle.

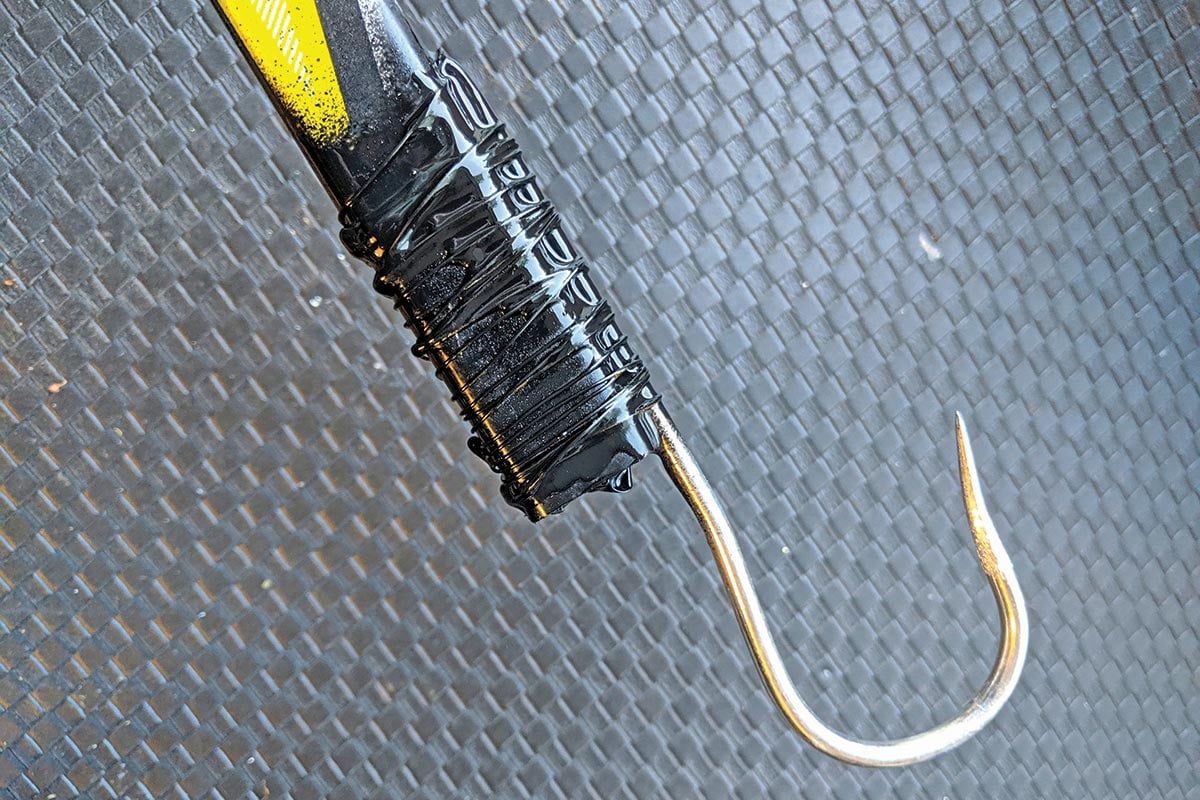

Hold the hook up against the handle and determine where the barb is going to be stuck into the handle. Mark it on the handle; then drill a hole in the handle so the barb fits in there and then outline the shank of the hook on the handle. Remove the hook; then, while holding a drill bit or routing bit on top of the handle lengthwise (parallel to the handle), burr out the outline of the hook shank so that way there is a channel where the shank will sit. Be careful if using bamboo or a somewhat hollow material not to go all the way through; just a little indentation will work fine. Mix some two-part epoxy and put some in the hole for the barb and channel for the shank. Lay the gaff hook in its place and wrap tightly with wire. Epoxy should also be added on top of the wire and hook for extra durability. Let the epoxy cure and harden fully. Once the epoxy is fully dried, it is time to wrap the shank and wire. Before doing this, it might be a good idea to hit the area with a quick coat of spray paint to seal up any exposed wire or hook shank that is showing. This will help prevent corrosion to those areas. The color doesn’t matter since it will be covered up anyway. Depending on the handle material, that could also be painted; it is good to paint wooden handles in particular as a sealant and to prevent the wood from getting waterlogged.

After the paint dries, it’s time to wrap the epoxy, wire, and hook shank. For this, electrical tape, heat shrink, or even paracord/string works fine. This is mainly for aesthetic purposes and doesn’t add too much support. The epoxy, wire, and barb are what mainly holds the gaff hook. Having some type of grip on the handle is important, especially if the wood is painted or the material is slippery. Remember, the user’s hands will most likely be wet. Figure out where the gaff handle is naturally gripped when you’re about to stick a fish and add the grips there. The grip can be anything from paracord wrapped around, hockey tape, or heat shrink rod grips; all work great! If using paracord or some sort of rope/string to make a grip, it is important to wrap it tight and finish off the ends with epoxy, so they don’t come undone. What’s nice about this gaff is that it’s something you made and is completely tailored to your liking. Next time NOAA’s offshore forecast leaves you stuck at home, give it a shot!